VARIO cutterbars.

VARIO cutterbars from CLAAS are synonymous with the best cutterbar table adjustment system in the market. With its VARIO 1380 to VARIO 500 models, CLAAS has made systematic enhancements to its proven VARIO cutterbar range.

- Use

The new generation of VARIO cutterbars is the first choice for harvesting grain and rapeseed. It is ideally suited to deliver high performance and high area output, whether operating in low or high-yield regions. The ability to adjust the VARIO cutterbar table for grain harvesting (short or long straw varieties) and rapeseed ensures an optimal crop flow at all times and therefore results in an increase in total machine performance of up to 10%.

The wide range of models, from the VARIO 1380 to the VARIO 500, allows the LEXION, TUCANO and AVERO to use VARIO cutterbars.

- Technology

- Cutterbar table with integrated rapeseed plates

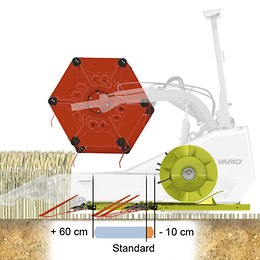

- Table position adjustable from – 100 mm to + 600 mm using the multifunction control lever

- Cutterbar table is unique in having an infinitely variable overall adjustment range of 700 mm

- Knife drive shaft with automatic, telescopic function

- Continuous knife bar and continuous reel (VARIO 930 to VARIO 500)

- Front attachment mechanical drive on one side (VARIO 930 to VARIO 500)

- Intake auger and knife bar mechanically driven via gearbox and drive shaft

- Reel with optimised reel tine carriers, wear-resistant tine tube bearings and a new design to reduce risk of wrapping and stalk take-up

- Angled cross-tube for a better view of the cutterbar table from the cab

- Intake auger height is infinitely adjustable

- Feeder housing, conveyor belt and reel can be reversed

- Stripper bars adjustable from the outside

- LASER PILOT for automatic steering system can be folded and adjusted without tools

Use in rice.

The VARIO cutterbars are equipped ex factory - or can easily be converted with a coated feed roller and a rice harvesting system - for optimal performance in rice.

Rugged drive train.

VARIO 930 / 770 / 680 / 620 / 560 / 500.

Thanks to its planetary transmission, the knife bar drive runs extremely smoothly. When the cutterbar table position is changed, the drive shaft adjusts telescopically at the same time, thus allowing work to continue in any position without the need for operator intervention.

The feed roller and knife drive are protected by individual overload clutches. This system allows the VARIO cutterbar to withstand the most adverse conditions and ensures reliable operation.

The VARIO cutterbars VARIO 1380, 1230 and 1080.

Optimal crop flow.

The VARIO cutterbars from CLAAS are designed for the most demanding field conditions. An optimal crop flow, clean cutting and a robust design are the defining characteristics of the three largest models, the VARIO 1380, 1230 and 1080. For these working widths, CLAAS uses the principle of the divided reel and intake auger as well as a divided knife bar.

Precise adjustment produces the best results.

An optimal crop flow starts right at the cutterbar, with the correct height setting of the intake auger being a particularly important factor. This is why height scales are provided at the adjustment points on the left and right sides and in the centre. This makes for effortless adjustment of the auger to the perfect height for every requirement.

The drive train.

Thanks to the mechanical drive via drive shafts, gears and large chains, the drive train is extremely efficient and requires little maintenance. The synchronised knife drive makes for a very smooth-running cutterbar. An overload clutch protects the entire drive train in the event of the intake auger becoming jammed. The knives are driven by gears on the left and right sides and are also protected by overload clutches.

Automatic reel torque control. VARIO 1380-500.

The hydraulic reel drive allows the torque applied to the reel to be adjusted automatically to cope with difficult harvesting conditions, such as lodged crops. An automatic height control system operates on the basis of the programmed pressure and sensitivity levels to maintain crop flow at all times.

Fast conversion to rapeseed. VARIO 1380-500.

Thanks to the integrated rapeseed plates and the ability to fit the rapeseed knives without the need for tools, conversion to rapeseed harvesting takes only a matter of minutes. The mechanical rapeseed knives are 33% lighter and provide 50% more cutting force. The entire adjustment range is available even with the rapeseed knives attached. The converted cutterbar still remains compact for transport.

Following the ground.

In order to ensure that excellent cutterbar guidance is also maintained over large working widths, the VARIO 1230 and VARIO 1080 models have two additional sensors. These are located in the centre and provide the AUTO CONTOUR system with an additional signal to identify the position of the cutterbar table.

Stabiliser wheels for improved ground adaptation.

In order to harvest at high speeds or on very uneven ground, you can fit two robust stabiliser wheels. These damp the movement of the cutterbar and so assist the AUTO CONTOUR ground adaptation. The height can be adjusted without tools. The integrated gas spring bears the entire weight of the stabiliser wheel during the setup procedure, thereby simplifying the task of the operator.

Rice harvesting with the VARIO and CERIO cutterbars.

The right equipment for a tough job.

Rice stalks are extremely tough. To achieve clean, top quality cutting results at a high rate in this hard and unforgiving material, the VARIO 930-500 and the CERIO 930-560 cutterbars can be adapted to the conditions.

Special knife guards and adjustable crop guards help ensure efficient cutting under even the most adverse conditions.

Hardened intake auger.

During rice harvesting operations, the machine has to cope with an excessive amount of dirt. To inhibit premature wear, the hardened intake auger has sintered edges.

The speed of the intake auger is reduced to ensure optimal feeding of the green and heavy rice plants.