CLAAS Forage Harvesting | VOLTO tedders.

The benefits for you.

- MAX SPREAD crop flow concept

- CLAAS power flow drawbar for smooth and safe movement over the ground

- Good directional control at any speed

- Adjusting to the situation: the optional guide wheel

- Patented power transmission: the PERMALINK finger clutch

- An easier tedding operation with robust spreader arms

- Robust, securely attached tines

Specifications | VOLTO

- VOLTO large series

Large series 1300 T 1100 T 1100 900 T 900 800T 800 700 Working width 13.00 10.70 10.70 8.70 8.70 7.70 7.70 6.70 Transport width 2.98 2.98 2.98 2.98 2.98 2.98 2.98 2.97 Rotors 10 10 10 8 8 6 6 6 Rotor diameter 1.70 1.50 1.50 1.50 1.50 1.70 1.70 1.50 Spreader arms per rotor 7 6 6 6 6 7 7 6 MAX SPREAD crop flow concept ● ● ● ● ● ● ● ● ● Series – not available

- VOLTO compact series

Compact series 80 65 60 55 45 Working width 7.70 6.40 5.80 5.20 4.50 Transport width 2.93 2.75 2.50 2.75 2.75 Rotors 8 6 6 4 4 Rotor diameter 1.30 1.50 1.30 1.70 1.50 Spreader arms per rotor 5 6 5 6 6 MAX SPREAD crop flow concept ● ● ● ● ● ● Series – not available

MAX SPREAD now fitted in all model series.

From 4.5 m to 13 m working width.

The 29.3° angle configuration of the spreader arms ensure high raking output, gentle crop feed between the rotors and an optimum spread pattern. It all adds up to higher output, and better work quality.

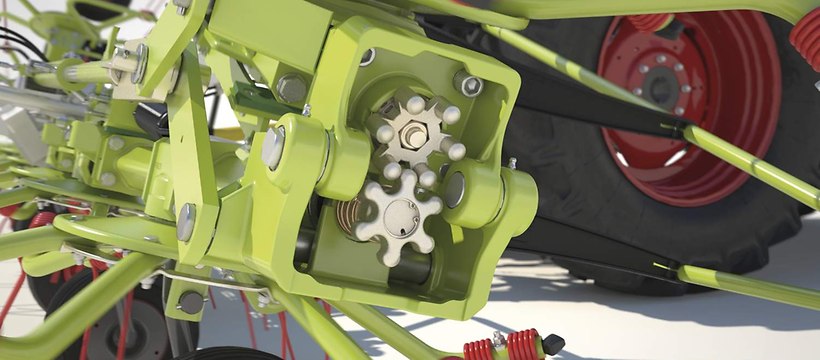

PERMALINK.

The PERMALINK drive concept ensures a continuous power transfer and is entirely maintenance-free. What's more, it facilitates deployment/retraction movements through 180°.

Maintenance-free.

Thanks to the combination of a continuously lubricated transmission and the PERMALINK finger clutch, the entire drive train up to the drive shaft is fully maintenance-free.

Headland spreading.

Edges straight as a die – the edge-tedding crop guard allows for consistent drying of the forage, including at the edges.