Field test of CLAAS ORIGINAL parts.

Since 2010, working in partnership with the Rendsburg branch of DEULA (German Training Centres for Agricultural Engineering), CLAAS has carried out intensive field tests with CLAAS ORIGINAL parts and non-genuine parts.

The testing process places great emphasis on using the parts in parallel under identical conditions. Only in this way is it possible to compare them and carry out a reliable assessment of their performance.

The documented results show that, apart from lower costs per hectare, CLAAS ORIGINAL parts offer much more:

- Maintenance of the machine's full performance

- Reduced fuel and maintenance costs

- Optimal work quality

- Longer service life

- Very high campaign performance

The most interesting results of the comparisons are shown below, categorized by machine.

CLAAS ORIGINAL parts for combine harvesters compared.

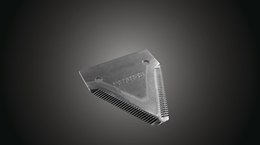

- Knife blades

Advantages of ORIGINAL knife blades compared with the non-genuine parts used in the field test:

- Less breakage

- Longer service life and period of use

- Reduced changeover times (negative costs)

- Maximum area output

The increased breakage of the non-genuine blades necessitates more frequent replacement of the knife blades and leads to more idle time during harvesting. Furthermore, there is increased wear of the double fingers and the knife drive.

Comparison of knife blades.

More information about CLAAS ORIGINAL knife blades is available here.

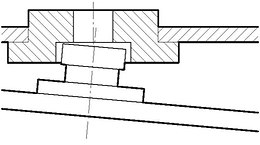

- Double fingers

Advantages of ORIGINAL double fingers compared with the non-genuine parts used in the field test:

- Sharper chop

- Lower fuel requirement

- Reduced load on the knife drive (knife heads and blade transmission)

- Maximum service life

CLAAS ORIGINAL – new

The precise gap ensures that the knives are guided with absolute accuracy. This results in a perfect cut combined with a longer service life while keeping the energy required to a minimum.

CLAAS ORIGINAL – 1,150 ha

Only slight erosion is visible at the gap after 1,150 ha. The integrity of the knife guide is unaffected. The cut is clean and helps save fuel.

After 1,150 ha, the non-genuine double fingers have clearly been used for too long. The energy required for the cutting action increases. This reduces the potential machine capacity utilisation by around 10 – 15 %. Thanks to the reduction in the time required to change the parts, a machine with CLAAS ORIGINAL double fingers can be used longer, thus achieving a higher seasonal performance.

ORIGINAL double fingers

CLAAS ORIGINAL double fingers have a predetermined breaking point. The knife guide remains intact in the event of contact with a foreign body, thereby preventing costly consequential damage.

Comparison of double fingers.

More information about CLAAS ORIGINAL double fingers is available here.

- Straw choppers

Advantages of ORIGINAL straw chopper knives compared with the non-genuine parts used in the field test:

- Optimum chop quality

- Optimum straw distribution

- Excellent work quality for straw incorporation (soil mix, straw rot, mice nests)

- Lower fuel consumption

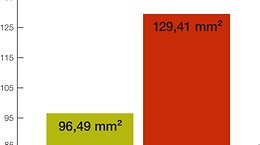

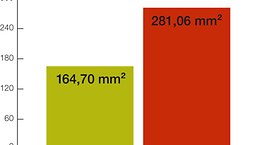

The columns show the average wear on the chopper knives after 100 and 150 ha. The difference between the CLAAS ORIGINAL and the non-genuine parts in terms of wear can be clearly seen. It is also clear that the wear, and therefore the fuel consumption, too, increases drastically between 100 and 150 ha. Replacing the blades in good time is recommended.

More information about CLAAS ORIGINAL straw chopper knives is available here.

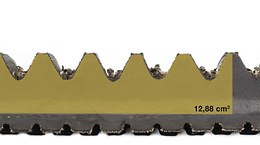

- PREMIUM LINE straw chopper knives

Advantages of ORIGINALPREMIUM straw chopper knives compared with the non-genuine parts used in the field test:

- Up to seven times longer service life per cutting side in comparison with the non-genuine part

- Best chopping results over the entire season

- Only one knife side per season (no idle times or change intervals)

- Optimum basis for subsequent work stages

With its price advantage and performance characteristics, the CLAAS PREMIUM LINE blade delivers significantly higher work quality which makes it a compelling choice.

Performance per cutting edge

Price per unit

Cost per ha

PREMIUM LINE

830 ha

325%

59%

ORIGINAL

150 ha

100%

100%

Non-genuine

100 ha

83%

124%

PREMIUM LINE straw chopper knives from the customer's point of view.

- Intake chains

Advantages of ORIGINAL intake chains compared with the non-genuine parts used in the field test:

- Less wear

- Longer service life and period of use

- Reduced changeover times (negative costs)

- Reduced wear on chain sprockets

The conveyor chains were installed in parallel in the feeder housing of a LEXION. After 3,000 ha, the radian measures clearly vary. These differences are due to the increased wear on the chain links and the bushes of the non-genuine chain. A complex disassembly procedure is required for their replacement.

More information about CLAAS ORIGINAL chains is available here.

- Drum belts

Advantages of ORIGINAL drum belts compared with the non-genuine parts used in the field test:

- Exact dimensions

- Optimal power transmission

- Very high tear strength

- Temperature resistance

- Lower fuel consumption

CLAAS ORIGINAL drum belts have side contact areas which are up to 10% larger. This leads to:

- Lower wear

- Longer service life

- Optimal power transmission

- Fuel savings

More information about CLAAS ORIGINAL drum belts is available here.

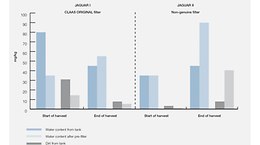

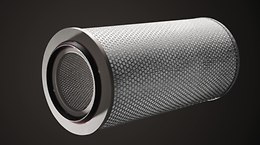

- Filters

Advantages of the ORIGINAL filter over the imitation filter:

- Higher filtration performance

- Lower suction resistance

- Up to 10% less fuel consumption*

- Reduced cleaning effort

- Reduced changing times

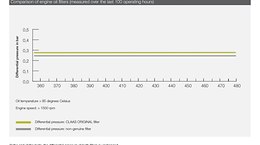

Already at the start of the field test, the suction resistance differential pressure of the non-genuine filter was greater than that of the CLAAS ORIGINAL. This means that the engine load with the non-genuine filter is greater, something which is also reflected in the higher fuel consumption. Total fuel consumption with the non-genuine filter is significantly higher and therefore significantly diminishes the saving represented by the lower purchase price.

More information about CLAAS ORIGINAL filters is available here.

CLAAS ORIGINAL parts for forage harvesters compared.

- Maize knives

Advantages of ORIGINAL maize knives compared with the non-genuine parts used in the field test:

- Longer service life, thanks to more stable coating

- Lower assembly costs, thanks to longer intervals between changeovers

- Fewer sharpening cycles, thanks to better coating

- Reduced fuel consumption, thanks to a sharper chop

- Improved chop quality, thanks to finer manufacturing tolerances

ORIGINAL maize knives

After 360 ha, the CLAAS maize knife still has an identifiable level of blade sharpness. The remaining 14 mm of the coating allow a total of about 1,200 ha to be covered.

(*The total coverage is determined by calculation. It is the hectare coverage provided per millimetre of coating starting from a knife in new condition.)

CLAAS ORIGINAL maize knives are distinguished by their high-quality basic material and long-life coating. This significantly reduces the need for re-sharpening and increases the service life. The need for early replacement, along with the time required for it, is thus eliminated.

- Grass knives

Advantages of ORIGINAL grass knives compared with the non-genuine parts used in the field test:

- Fewer sharpening cycles

- Higher output per hectare

- Longer-lasting sharpness means lower fuel consumption

- Reduced load on the drive train

ORIGINAL grass knives

After 439 ha, there is a residual usable coating thickness of about 5 mm. Further use for about 100 ha is possible.

CLAAS ORIGINAL grass knives are remarkable for their extended period of use. Thanks to this benefit, the higher purchase costs quickly become relative, as the lower fuel consumption and the reduced changeover times make themselves felt.

- Shear bars

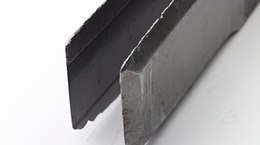

ORIGINAL shear bar, 360 ha

CLAAS ORIGINAL shear bars have a significantly sharper edge. Together with the CLASS ORIGINAL knives, they ensure optimal chop quality.

CLAAS ORIGINAL shear bars, in combination with the CLAAS ORIGINAL knives, ensure optimum chop quality. In addition, they offer a service life that is up to 100% longer, thereby saving an equal amount of changeover time.

More information about CLAAS ORIGINAL shear bars is available here.

- Accelerator paddles

Advantages of ORIGINAL accelerator paddles compared with the non-genuine parts used in the field test:

- Operational safety, thanks to greater durability

- Less readjustment at the rear of the housing

Thanks to their highly wear-resistant coating, CLAAS ORIGINAL accelerator paddles achieve a significantly longer service life in comparison.

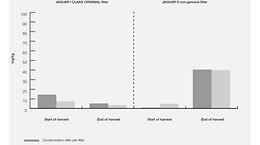

- Filters

CLAAS tests in the field. Only CLAAS has compared ORIGINAL filters and non-genuine filters in the field during an entire harvest season. In order to ensure that the tests were conducted under real-world conditions, established non-genuine filters were purchased in the market. The filters were then used on identical machines under comparable operating conditions. The interesting results of this field test are presented clearly and comprehensibly.

In cooperation with a contractor in the Eifel region of Germany, a comparison between ORIGINAL and non-genuine filters in two CLAAS JAGUAR forage harvesters was carried out over the course of an entire harvest. The non-genuine filters tested were selected carefully with regard to their comparability.

The field tests were conducted using two identical CLAAS JAGUAR machines in order to ensure comparability between ORIGINAL and non-genuine filters.

To make the field tests as authentic as possible, a professional customer whose forage harvesters each clock up as many as 1000 operating hours during the harvest season was selected.

In order to ensure the comparability of the filters, the non-genuine filters were purchased through established sales channels (e.g. online shops). According to the suppliers, the non-genuine filters tested corresponded to the CLAAS ORIGINAL filters in terms of quality, filtration performance and dimensions.

Oil filter results:

The test showed that this non-genuine filter is able to offer almost comparable performance. Nevertheless, doubts remain as to whether the maintenance interval prescribed by the engine manufacturer can be maintained. Furthermore, it is important to bear in mind that a non-genuine filter is not approved by the engine manufacturer.

Video: Engine oil filter testing

Hydraulic oil filter results:

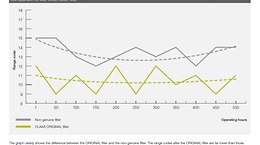

The graphs clearly illustrate the reality: the CLAAS ORIGINAL hydraulic oil filter is able to filter significantly more foreign particles out of the hydraulic oil. It is clear from the measurements that the hydraulic oil in the machine with an ORIGINAL filter is cleaner.

Video: Hydraulic oil filter testing

Air filter results:

- Higher filtering performance

- Lower suction resistance

- Up to 10% lower fuel consumption

- Reduced cleaning effort

- Reduced changeover times (negative costs)

Video: Air filter testing

Fuel pre-filter results:

The non-genuine filter does not reach the scheduled maintenance interval. It would have to be replaced earlier. In addition, considerably greater amounts of water and dirt particles entered the fuel system (e.g. through refuelling in the field) than were filtered out. The overall contamination level actually exceeds the limit set for the sale of diesel fuel in the EN 590 diesel fuel standard (24 mg of dirt per kg of diesel fuel). The CLAAS ORIGINAL filter, by contrast, protects your injection system against contamination by dirt and water all the way to the scheduled maintenance interval.

Fuel filter results:

The inferior filtration performance of the non-genuine filter resulted in more dirt particles entering the fuel system. The contamination level actually exceeds the limit set for the sale of diesel fuel in the EN 590 diesel fuel standard (24 mg of dirt per kg of diesel fuel). It seems likely that the dirt content that was initially retained was suddenly released when the filter became oversaturated. In view of the degree of contamination, it would have been necessary to change the filter before the replacement interval.

Video: Fuel filter testing

Interested in learning more about filters? You can download our Focus on filters brochure here.

CLAAS ORIGINAL parts for balers and forage harvesting machines compared.

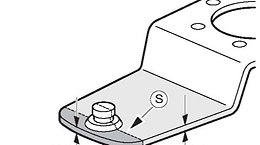

- Leaf springs (CLAAS DISCO)

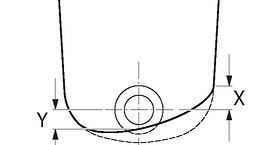

The illustrations show the wear limit at which it is advisable to change to a new part. Only parts which function optimally will ensure the safe and reliable operation of your CLAAS machine. Do not use parts beyond the wear limit and ensure that they are changed in time.

Take note of the wear limit indicated by the thickness of the

mower blade holder:

W: 3 mm

Z: 4 mm

Also replace in the event of visible cracks or heavy wear of the weld seams (S) on the mower blade bolt.Replacement in the event of deformation (bending) of the mower blade holder or if the mower blade bolt is no longer straight in the disc mounting hole.

- Baler knives

Advantages of the ORIGINAL baler knives compared with the non-genuine parts used in the field test:

- Low wear

- Sharper chop over a longer period

- Lower fuel consumption

- Less time required for resharpening

CLAAS ORIGINAL baler knives in comparison with two different non-genuine knives. After 2,700 bales, the lower degree of wear on the CLAAS ORIGINAL knives is clearly recognisable. Owing to the better material quality and the sophisticated manufacturing process, the chop quality is maintained longer, significantly reducing the need for sharpening. This means more bales per knife.

More information about CLAAS ORIGINAL baler knives is available here.

- PREMIUM LINE baler knives

Actual number of bales per year

Actual number of bales per year

Sharpening cycles

PREMIUM LINE

815

20

66%

ORIGINAL

815

30

100%

CLAAS PREMIUM LINE knives have a significantly reduced requirement for sharpening. This increases the overall performance of the knives and saves time and fuel.