The knotter – a symbol of better things to come.

What exactly is a knotter?

Perhaps the sewing machine principle lay behind the invention of the knotter, as the tying device in the straw binder is called. The needle in a sewing machine pushes into the material and pulls loops through the textiles as they flash past. In the same way, the knotter in the straw binder loops the binding twine around the bale of straw with the help of a needle and a knotter hook, and then pulls it tight.

This system works well as long as the binding twine has a constant thickness. If its thickness varies, the twine breaks and the bundles of straw fall apart. The American company McCormick launched a very effective device to bind straw onto the market as early as the end of the nineteenth century, but the binders were successful to only a limited degree in continental Europe, and were constantly breaking down. August Claas then developed a knotter hook with a jaw that had a limited range of movement. This added flexibility meant that binding twine of any thickness and composition could be processed, and, in principle, it would always hold.

The twine was of poor quality, particularly in the period of shortages following World War I. As a result, the CLAAS invention was of huge economic importance in the field of agriculture.

The knotter device was issued with patent No. 372140 in 1921, as the very first patent of Gebr. Claas. The legendary knotter bill hook with floating jaw was patented in 1923 under No. 414212. Essentially, the knotter still works in much the same way today, and straw bales all around the world are still firmly tied with twine. Straw is well worth protecting as a valuable and renewable resource, and the knotting process maintains the shape and quality of the bales.

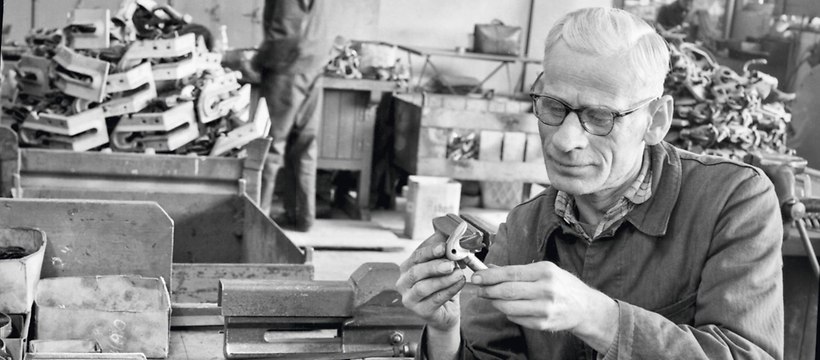

Quality calls for a combination of high-level manual work and precision crafting. Georg Szyszka inspecting the knotters for fitting in straw balers – a picture from the year 1962.