Many Places. One Passion.

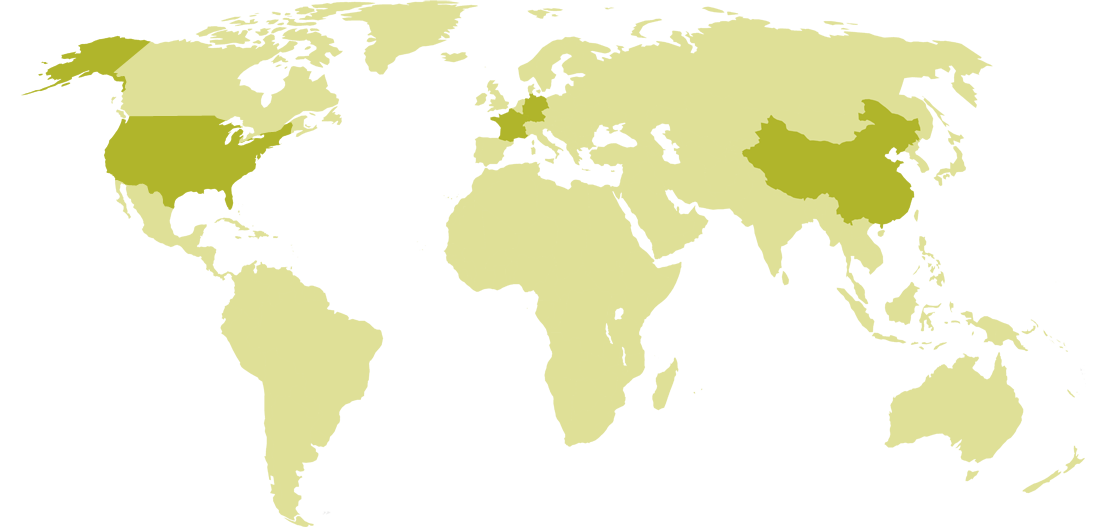

CLAAS operates more than ten production plants worldwide – all united by a passion for agriculture. If it has the CLAAS name on the outside, you can be sure it has the CLAAS quality on the inside – from products to corporate culture. But how does the company manage to uphold the highest standards globally and create a community? You can find out on this page. Get to know selected production plants in more detail – and meet the people behind the machines. If you want to discover even more about global production at CLAAS, you can find all our production plants here.

Four CLAAS production plants

Insights from our colleagues

1 Job. 3 Locations.

Questions for CLAAS

1. In how many countries does CLAAS have production plants and where are they located?

We basically distinguish between production (e.g. including the body shell) and final assembly. We manufacture at the following locations:

- Germany: Harsewinkel, Paderborn and Bad Saulgau

- France: Le Mans and Metz-Woippy

- Hungary: Törökszentmiklós

- USA: Omaha

- India: Chandigarh

- China: Gaomi

- Russia: Krasnodar

Final assembly takes place in Usbekistan (Taschkent) as well as Krasnodar (in addition to local TUCANO production). We also source machines from partnerships with Liebherr (SCORPION, TORION) and Agritalia / Carraro Tractors (NEXOS, ELIOS).

2. Why do CLAAS products routinely perform so well in tests?

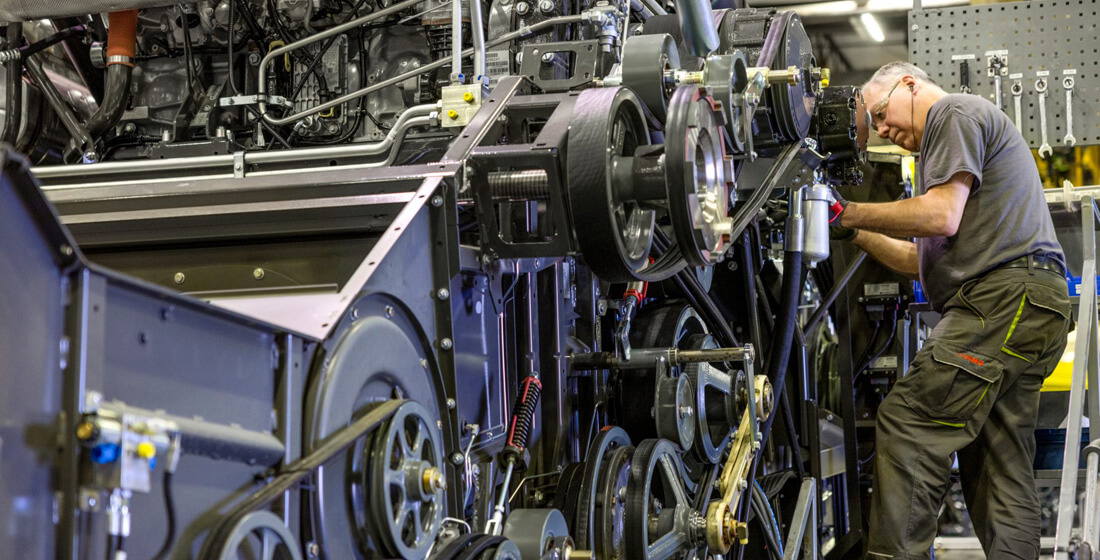

The fact that our products are rated good or very good in independent tests is due to a number of factors. First, we have years and often decades of experience and expertise in many product areas. This puts us at the forefront of cutting-edge design when it comes to combine harvesters, forage harvesting equipment, forage harvesters, TERRA TRAC crawler tracks and CEMOS assistance systems.

Then we have innovative employees who are attuned to the needs of our customers – many of our developers come from a farming background themselves. Furthermore, direct feedback from customers all over the world helps us to continually refine and improve our products.

Another important factor is that we focus development not only on the reliability, productivity, efficiency and performance of our products, but also on low maintenance and wear costs combined with long-term value retention and exceptionally long service life.

3. Does CLAAS manufacture everything in-house? What is the level of vertical integration?

No, we do not make everything in-house, that would not be commercially viable. Depending on the products, our level of vertical integration is around 20 to 25 percent. Take components such as diesel engines, for example. We don’t have sufficient volumes to justify in-house production so instead we rely on engineered components that are also used in HGVs or construction vehicles.

Furthermore, many special manufacturing processes – including plastics processing, electronics production, and metal forging and forming – can often be outsourced more cheaply and in high quality.

However, we tend to manufacture large-volume welded components in-house ‘just in time’. We generally assemble and commission our products ourselves as well.

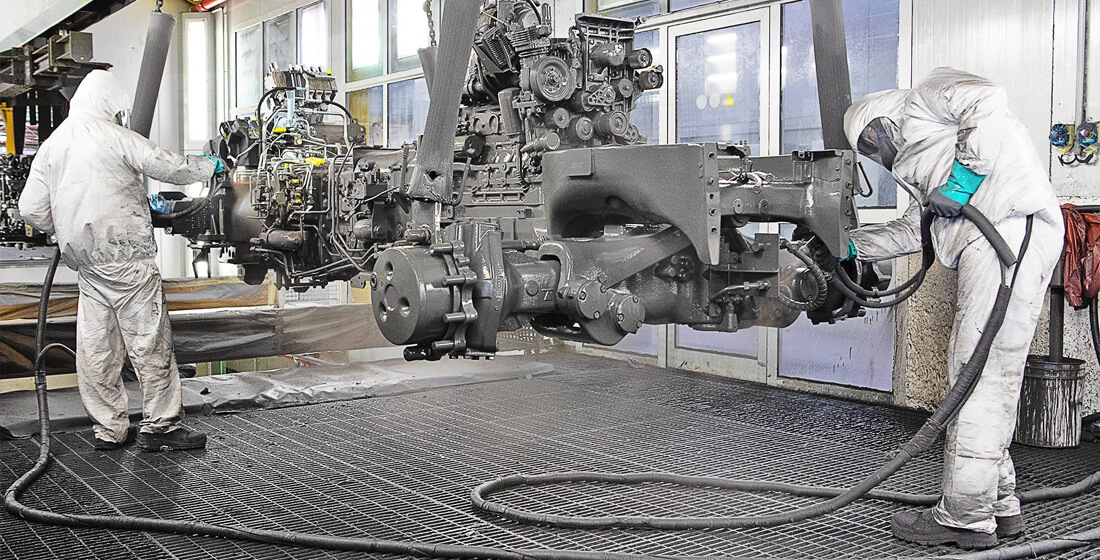

4. How does CLAAS ensure that its products are consistently produced to the same standard?

First and foremost, our highly qualified and skilled staff are responsible for the excellence of our products. In addition, we have put in place a range of procedures to ensure the quality of our machines.

- Quality management: The group-wide quality management system is regularly audited both internally and externally and continuously improved.

- Supplier selection: Just as we do from ourselves, we expect the highest standards of quality from our suppliers (see question 5: What standards do CLAAS suppliers have to meet?). To satisfy these standards, we select our suppliers with utmost care in accordance with a standardised process. We regularly check our standards to ensure that they comply with automotive standards.

- Validation of components: We use simulation-based methods to test how components and assemblies behave under continuous load and peak loads.

- Constant field testing: During development and pilot production, we test our products in the field to detect possible quality problems before starting series production. During series production, we then test the machines remotely both off-line and online so that even the slightest discrepancies can be corrected.

- Inspection of components: Purchased parts at CLAAS undergo routine incoming goods inspections. Parts manufactured in-house are regularly checked to ensure they conform to specifications.

- Quality gates: QGs are part of our coordinated and standardised manufacturing and assembly processes. They enable us to identify and rectify deviations directly on site. When deviations occur, established internal quality control loops are immediately set in motion – to rectify the deviation in the short-term and eliminate the actual cause of the error permanently. CLAAS also uses a group-wide IT app to support the process of fault finding and rectification.

- Machine test benches: These test benches integrated into the assembly line test whether the machines meet the specified load profile for customer use.

- Product audits: We regularly select machines at random and test them for several hours from the customer's point of view.

- Pre-delivery inspection: We give machines a final inspection before delivering them to dealers. This means that we can be sure that our products comply with all customer requirements.

5. What standards do CLAAS suppliers have to meet?

We are a premium manufacture, so our suppliers are required to meet the highest standards in terms of quality, logistics, costs, innovation and motivation. These aspects are reviewed annually as part of our supplier assessment process. Our suppliers should also be willing to engage in continuous improvement.

We attach great importance to developing good working relationships with our partners. Our aim is to ensure reciprocal preferential treatment between us and our suppliers.

6. What are the standards on which CLAAS training and professional development are based?

We educate and train our staff according to the following principles:

- Objective- and needs-based approach: For us, further development means helping our staff drive CLAAS forward – now and in the future. The CLAAS corporate strategy and objectives determine the development needs of our workforce. To this end, we take a systematic approach to analysis and planning in order to prioritise training opportunities. In individual discussions with employees, we identify where their focus of professional development should lie – other than statutory training such as occupational health and safety.

- Focus on practice and transfer: We base training and development on the 70-20-10 model: 70% of the time our staff learn on the job, e.g. by taking on new responsibilities. 20% of the time they learn informally from others, e.g. through feedback. And 10% of the time they learn formally in professional development programmes and on- or off-line training courses. It is important that the courses and programmes build on one another, encourage reflection and have a large practical element to facilitate consolidation. Formal further education and training programmes are delivered through a combination of methods tailored to the target group.

- Transparency: Eligibility requirements for our professional development opportunities are transparent. And the assessment criteria are based on systematic frameworks such as the CLAAS skills model.

- Individual responsibility: Every employee has a unique potential that deserves to be recognised and nurtured. Employees take responsibility for their own professional development – from start to finish. Our management team and HR Department play a coaching role in helping employees achieve their development goals.

- Evaluation and quality control: Employees are encouraged to provide feedback after each person development activity. This enables us to assess the success of each measure. In addition, we benchmark our results with other companies to validate and enhance our development opportunities.

7. How does CLAAS create a common employee culture in locations all around the world?

One thing that unites us all is that we are a family business with shared values. We also share an enthusiasm for the CLAAS brand and for our products, as well as the associated shared vision of making our customers the best in their field.

And of course, the friendly and informal working environment epitomised by the personal commitment of each and every employee around the world is key to our culture.

8. How does CLAAS support local farmers and agricultural service providers?

We support local farmers and agricultural service providers primarily by providing innovative and efficient products and our experienced, highly professional sales and service partners:

- CLAAS machines: Our tractors and harvesting machines are among the most efficient on the market; they have low operating costs and top-quality drive and chassis technologies which are fuel-efficient and soil-friendly – including the TERRA TRAC crawler tracks and CTIC tyre pressure control system.

- Assistance systems: We are at the forefront in this area too. A wide variety of CEMOS assistance and process optimisation systems relieve the burden on drivers so that they can focus on their job during long working days. The technology also enables less experienced operators to deliver outstanding results.

- Data documentation and analysis: We provide solutions for data documentation and analysis such as TELEMATICS and CLAAS connect which are aimed primarily at contractors and arable farms.

- Precision farming technologies: Users of our machines can cut down on inputs with the aid of digital tools such as automatic steering systems, guidance systems and Section Control. We offer digital solutions through 365FarmNet from fleet management and farm management software to field mapping, crop cultivation and herd management.

- DataConnect: Our connected machines are compatible with the cloud-to-cloud DataConnect platform. This means that our customers can view machine data across their entire fleet – from CLAAS, 365FarmNet, CNH and John Deere.

Furthermore, we attach great importance to having an extensive, network of professional dealerships who offer outstanding service:

- Spare parts: We ensure a fast and reliable supply of high-quality spare parts which includes several product lines – not just for new CLAAS machines, but older models too.

- Warranty: The manufacturer's warranty can be extended by up to eight years or 8000 operating hours, providing the financial security that businesses need to plan with confidence.

- Used machines: The global CLAAS used machine business is regarded as the most professional in the industry. Certified used machines with warranties give purchasers peace of mind.