Ergonomic CEMIS 700 control terminal.

- New terminal with convenient user navigation and touchscreen

- 7” display with very high resolution

- Two camera inputs

Robustness and reliability under the toughest operating conditions have made the ROLLANT the best-selling silage baler in the world. Reinforced rollers, intelligent chain lubrication and the optional MAXIMUM PRESSURE SYSTEM (MPSII) in the tailgate ensure that it stays that way.

The rotor blades of the feed rotor are arranged in dynamic helixes to ensure uniform intake and efficient throughput. The system is particularly well-suited to delicate types of forage such as alfalfa. The helical arrangement protects crops and produces top-quality forage.

The ROTO CUT feed system runs at over 7,000 chops per minute. Four rows of tines gather in the crop evenly through the knives. The crop is guided precisely over the centre of the blades and chopped exactly. A special system of strippers keeps the rotor clean at all times. The precise angle of the feed tines effectively prevents crushing of the crop as it passes through. Uniformly chopped slices improve silage quality and facilitate easy distribution both in silage preparation and later on in the feed mixer.

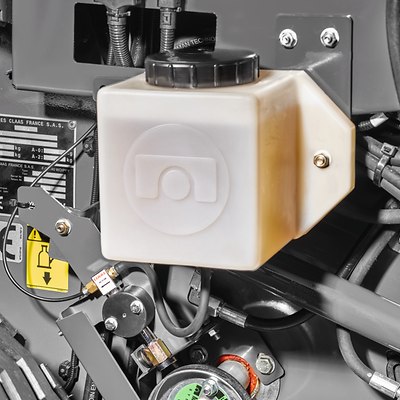

The new distribution units in the 6.3-litre lubricator supply each individual chain with exactly the amount of oil needed for long and smooth-running operation. You can save on cash, in addition to saving valuable maintenance time.

The proven ROLLANT fixed-chamber concept is subject to continuous development and improvement by our engineers. For the new generation, they have revised the design completely. One glance at the new lines makes it clear that this is one of the most robust balers in the world.