The CLAAS corncracker concept.

An optimal solution for every requirement.

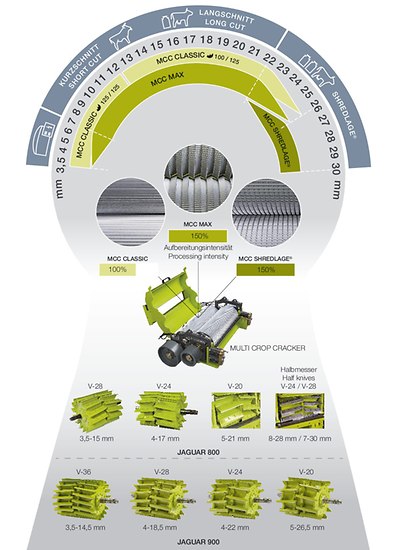

With the MCC SHREDLAGE®, CLAAS is expanding its range of corncracker systems for special applications and offering an interesting complementary solution for contractors as well as for professional dairy producers with their own equipment. The CLAAS MULTI CROP CRACKER concept (MCC) with a standardised cracker housing module and corncracker rollers which can be replaced quickly will also include the long-established and proven MCC CLASSIC system in future. It is designed for conditioning short-chopped silage in the 3.5 to 12 millimetre length range, such as is used primarily in biogas systems but is also suitable as feed for dairy cattle. Another addition is the MCC MAX corncracker system which has been newly developed by CLAAS and which meets the growing demand for long-chopped silage. This system allows the conditioning of a very wide range of different chop lengths from 7 to 22 millimetres and therefore represents a highly flexible corncracker variant for contractors who have to work with a number of different farms.

The chop length scale in the diagram shows the boundaries of these key application areas. Short chop lengths from 3.5 mm are the principal domain of the MCC CLASSIC. This cracker with 125 / 125 teeth (250 or 196 mm diameter) and a 30% speed differential is therefore primarily designed for conditioning maize silage for biogas facilities. At the same time, the MCC CLASSIC remains a well-established and proven technology for chop lengths up to 12 mm which have traditionally been used in the preparation of maize silage as feed for dairy and beef cattle. An exchange roller with only 100 teeth, which can be ordered through the parts system, for example, allows the application spectrum of this cracker to be extended into the chop length range above 12 mm.

The newly developed MCC MAX is the perfect solution for meeting requirements which can change on a daily basis, from short chop lengths all the way up to 22 mm lengths, without the need to change the rollers. The newly developed friction segments with combined friction and cutting surfaces as well as the 30% speed differential lead to more intensive processing by friction with additional cutting and shearing effects which were impossible in the past. The key benefits of the MCC MAX are therefore not only its ability to operate flexibly across a huge chop length range, but also the more intensive conditioning and the more pronounced effects on the silage structure.

The MCC SHREDLAGE® meets the requirements of the feed strategy that shares its name. Roller elements with a sawtooth profile and a helical groove, 110 / 145 teeth as well as a speed differential of 50 % condition the silage in such a way that milk and meat yields are increased. Depending on the DM content, the system can deliver chop lengths of 26 to 30 mm. At higher DM levels, chop lengths as short as 21 mm are possible. SHREDLAGE® is long-chopped maize silage which also undergoes special conditioning. SHREDLAGE® is long-chopped maize silage which has also undergone special conditioning. This special conditioning can only be achieved with the genuine SHREDLAGE® corncracker rollers.

In future, the SHREDLAGE® rollers will be produced under licence by CLAAS itself at the CLAAS Industrietechnik facility in Paderborn where the well-known sawtooth profile rollers are also manufactured. Like the MCC MAX, the MCC SHREDLAGE® will be available from 2016 as an ex factory option or for retrofitting to the JAGUAR 870, 880* and 950 to 980 models.

* North America only