CEMOS operators are unbeatable.

The advantages of CEMOS.

- Reduces tyre wear

- Reduces soil compaction by optimising tyre pressure

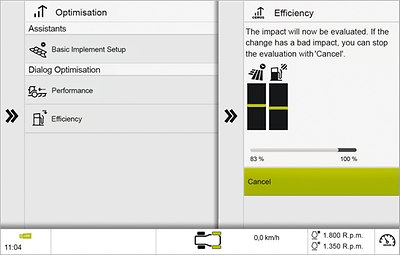

- Reduces operating costs by increasing work rates

- Utilises the full potential of the machine

- Reduces implement wear (plough assistant)

- Improves carbon footprint of the farm

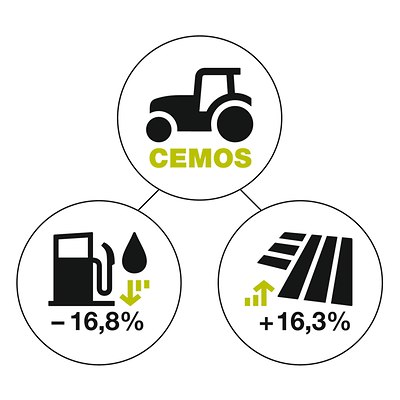

- Up to 16.3% higher work rate (ha/h)

- up to 16.8% lower fuel consumption (l/ha)

- Eight out of ten test participants managed to reduce their fuel consumption while at the same time increasing their work rate

Interactive soil protection.

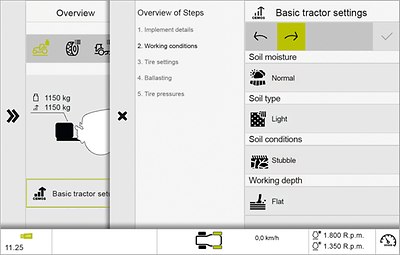

The first silver medal goes to the integration of soil compaction risk analysis into the self-learning operator assistance and process optimisation system CEMOS for Tractors. The compaction risk is calculated on the basis of scientific field trials and formulae developed by Bern University of Applied Sciences (BFH-HAFL) in cooperation with the Agroscope Research Institute in Reckenholz, Aarhus University in Denmark and the Swedish University of Agricultural Sciences (SLU).

The universities and institutes combined their knowledge to create the Terranimo® model for predicting soil compaction, which is freely available as a web-based app. The Innovation Committee recognised the additional benefits of linking this tool to CEMOS: by integrating this specialist knowledge into the farm machine itself, the operator does not have to enter any additional data because CEMOS already provides it. A display on the CEBIS terminal informs the operator if the current tractor-implement combination represents a risk of harmful soil compaction under the prevailing soil conditions. If the operator confirms the suggested optimisation settings, the information is fed straight back into the current risk assessment performed by the function.

DLG certification.

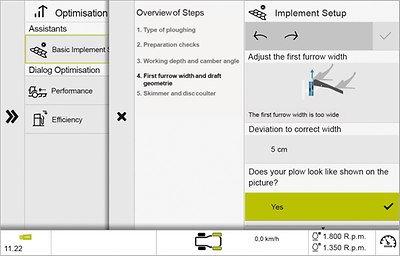

During and after Agritechnica 2019 we challenged our customers and visitors to a dual with CEMOS for tractors: professional drivers head-to-head with a professional system – that's how it started.

We selected ten particularly experienced farmers and tractor drivers from four European countries from the large number of applicants who responded to our request. The CEMOS Dual took place in September 2020 on a farm in eastern Germany.

Georg Schuchmann from DLG Test Center Machinery and Farm Inputs was there to ensure that the test was performed under objective conditions. He measured the speed, fuel consumption, work rate, working depth and quality of work for each test drive. Under the watchful eyes of the DLG, the experience of the drivers was pitted against the capabilities of the CEMOS operator assistance system – and the “DLG-approved” seal was in the bag. This DLG award confirms the effectiveness of CEMOS in terms of fuel savings (up to -16.8%) and cultivation work rate (up to +16.3%). Eight out of ten test participants managed to reduce their fuel consumption while at the same time increasing their work rate.

You can find the official test report here.

CEMOS 120 seconds

Humans versus machine!

We put our best drivers up against CEMOS for tractors – and the result was a surprise for both parties.