New top-of-the-range class, with the APS HYBRID

With the LEXION 480, CLAAS entered a new dimension of power and performance. The proven APS threshing system from the MEGA was fitted with a larger drum. Rather than operating with straw walkers, the machine had two axial separator rotors. The LEXION also set new standards in terms of user-friendly operation, driver comfort and cab environment.

1996

LEXION 400 series – a milestone in combine harvester design

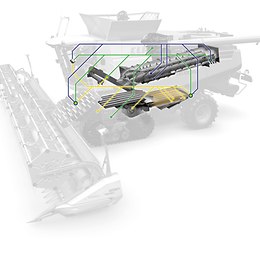

The LEXION 480 large combine harvester reached new performance peaks. CLAAS unveiled the LEXION in 1995, and put it onto the market in 1996. In the LEXION, CLAAS combined the APS threshing system with the revolutionary ROTO PLUS grain separating system. This was the first time CLAAS had departed from the traditional threshing drum diameter of 450 mm. The LEXION 480 was the first CLAAS combine harvester with a threshing drum diameter of 600 mm. LEXION machines also featured a host of other performance-boosting components. The cab had been completely redesigned, for greater driver comfort, while the CEBIS integrated on-board computer took over a wide range of functions, further considerably easing the driver’s workload. Another development milestone was the use of LASER PILOT and GPS PILOT, which made controlling the operation of the combine harvester much easier than before.

2001

MEDION – economical, flexible, universal

CLAAS launched the MEDION for the 2001 harvest. The MEDION was the successor series to the DOMINATOR with conventional threshing system. Thanks to their flexibility, the machines were also suitable for small land parcels and different crop types ranging from fava beans to clover seed. The MEDION was conceived in particular for farms that sought to retain their own machinery for grain harvesting, or for farms that shared the use of a combine harvester in order to improve capacity utilisation.

2003

LEXION 500 series – in a class of its own

In 2003, CLAAS unveiled the fully overhauled LEXION 500 series under the title LEXION – NEXT GENERATION. A raft of technical innovations brought further performance enhancements, including electric adjustment of the rotor separation areas, for example. Newly introduced features included the quick stop for front attachments and the GRAINMETER, which displays the volume and composition of the returns on the CEBIS screen.

2005

The LEXION 600 series – definition of a new class

The LEXION 600 was launched as a top-of-the-range model in 2005. CLAAS engineers further enhanced its performance profile, making it the world’s most powerful combine harvester. In favourable conditions, the machine is capable of harvesting 60 to 70 tonnes of wheat per hour. Theoretically, the machine is therefore capable of harvesting a sufficient volume of grain daily to supply bread to a city of 350,000 inhabitants. With the LEXION 600, CLAAS introduced the largest and most powerful combine harvester the European market had ever seen.

2008

TUCANO – premium segment at the top of the mid-range

In 2008, CLAAS set new standards in the upper mid-range category with the development of the TUCANO. Thanks to its versatility, the TUCANO can be used on any size of farm, for virtually any kind of task. With its big brother, the LEXION, providing inspiration, the efforts of CLAAS engineers furthermore ensured that the machine embodied key top-class performance characteristics. The tried-and-tested, high-performance APS threshing and separation system, for example, is installed in all 400-series TUCANO models. The machine has also been available with the APS HYBRID SYSTEM since 2009. Intelligent assistance systems such as the new AUTO CONTOUR system for cutterbars and the AUTO PILOT and LASER PILOT steering systems can be conveniently operated by the driver via the electronic CEBIS on-board information system. Additionally, a wide selection of different front attachments facilitate use for different harvesting tasks.

2010

AVERO – the new compact class

At the same time that the new TUCANO with APS HYBRID SYSTEM was launched on the market, CLAAS unveiled an additional combine harvester model, the AVERO, at Agritechnica 2009. The machine represented a new compact class between the DOMINATOR 150 and the TUCANO. The AVERO was conceived for smaller and medium-sized farms that rely increasingly on the use of their own machinery. The machine is equipped with numerous features from predecessor CLAAS combine harvesters, such as the APS system, 3D cleaning and the high-performance VARIO cutterbar. A particular benefit is that the machine can utilise the same cutterbars as the TUCANO and LEXION.

2011

LEXION 700 series – growing demands

The most powerful combine harvesters from the CLAAS range tread new paths: two redesigned series (the 700 and 600) have a wealth of new features, and boost productivity still further. With the 700 series, CLAAS is defending its leadership position in the combine harvester market. Fitted with the new TERRA TRAC half crawler track assembly, the LEXION 770 reaches a road speed of 40 km/h, making it the world’s fastest combine harvester. As well as having a new cab, the LEXION is fitted with a new electronic system which improves the entire electronic control system. This ensures fast communication across the entire on-board network.

2013

LEXION – the new generation

The LEXION 770, recognised as the world’s most powerful combine harvester, has now been surpassed. The new LEXION 780 provides an unprecedented mix of maximum functions, power, stamina, versatility and comfort. A world first here is the CEMOS AUTOMATIC, with which CLAAS has revolutionised the operation of a combine harvester machine. This makes the LEXION the world’s first combine harvester with a fully automatic harvesting function. The new system controls the numerous setting parameters, such as residual grain separation, and completely independently, and continuously adjusts the machine to the harvesting conditions. This enables the operator to harvest faster and for longer periods, with optimum harvesting outcomes. Another new feature is DYNAMIC COOLING, a revolutionary cooling concept, which, as well as dynamically controlling the cooling output, counters rising dust with its new airflow principle, practically performing a continuous cleaning function. Another innovation is the four-link axle, developed and patented by CLAAS. This provides unimpaired manoeuvrability even on large tyres up to 1.65 m high (30” rims), and incomparable stability and pulling power. Further innovations in the top-of-the-range class of combine harvesters include a larger grain tank with even more capacity than before (12,500 l) and faster discharge, at up to 130 l/s, as well as state-of-the-art engines meeting the most stringent new exhaust standards (Tier 4i).

2020

True revolutions start in the heart

Revolutions begin with a vision which is borne in the heart. Which prompts us to think about things in a new way. Which evolves into a mindset and so becomes a driving force for innovation. Like the new LEXION, which we have redesigned from the ground up to meet your needs: more intelligent and efficient than ever, it sets new standards for combine harvesters. A real revolution, in fact.